Select Language

- All

- Title

Select Language

Payment Type: L/C

Transportation: Ocean

| Types | |

| Contact Now |

Model No.: Customized

Brand: YONGRONG

Place Of Origin: China

Material: Electrical steel

| Selling Units | : | Piece/Pieces |

|---|---|---|

| Package Type | : | Wooden case, anti-rust bag |

| Picture Example | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

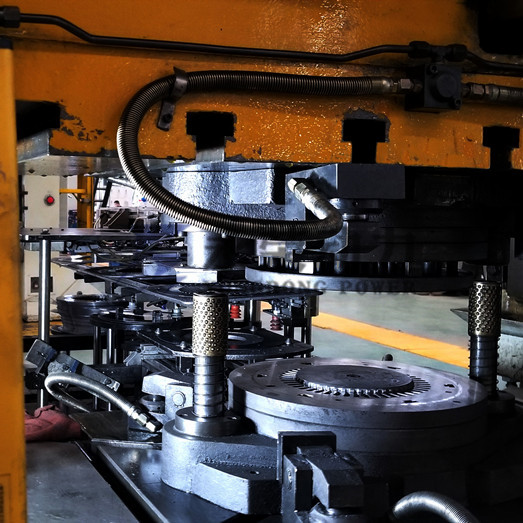

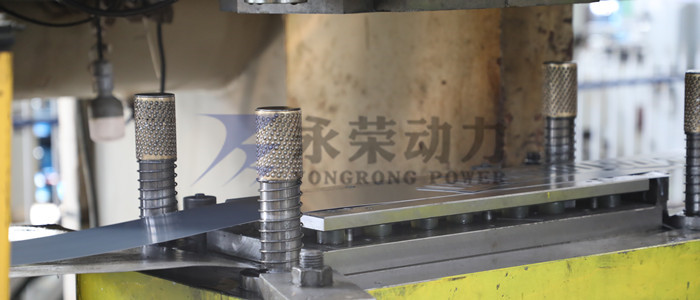

In terms of stamping, some complex rotor laminations of permanent magnet motor may need stamping twice, while compound stamping can rush out a complete Motor Lamination only once. By this token, the production rate of compound stamping is very fast, also, it has good flatness and concentricity. Although the cost of the mold is not cheap, when costs allocated to each motor lamination, the compound stamping scheme is both economical and efficient, so it especially suitable for medium and large volume production.

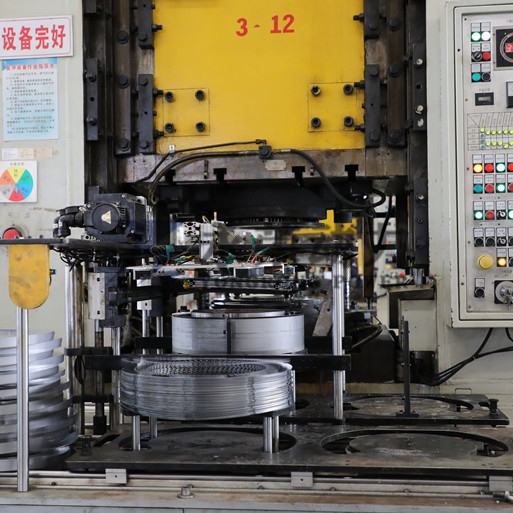

Because Compound Punching is suitable for medium motor Stator Lamination, the whole mold is mixed between the piston and the press base, the mold size is large. The discs are stamped into laminations in a fraction of a second, it's running speed is much faster than the speed of rotary grooving, the entire feeding and output process can be operated by automated systems or workers.

Compound presses are well suited for automated feeding and output systems, it can maximize the capacity of the press and greatly improve productivity, so more than half of our compound presses are equipped with automated systems.

The production capacity of compound punch depends on the performance of the punch and the size of the base(used for mounting molds). Compared with rotary grooving, the cost of composite mold is much higher.

Packaging: Wooden case, anti-rust bag

Transportation: Ocean

Place of Origin: China

HS Code: 85030090

Port: QINGDAO,SHANGHAI

Payment Type: L/C

Incoterm: FOB,CFR,CIF,EXW,DDP,DDU,Express Delivery

Hot Products

SEND INQUIRY