Select Language

- All

- Title

Select Language

Payment Type: L/C

Transportation: Ocean

$1-9999 /Pack/Packs

| Types | |

| Contact Now |

Model No.: Series Of Y

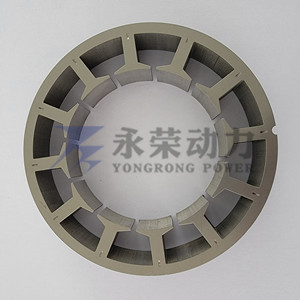

Brand: YONGRONG

Warranty Period: 3months-1year

Place Of Origin: China

Material: Silicon steel

Size: All Sizes

Style: All Styles

Paintcoat: Yes

Custom Goods: Yes

Application: Motor

Color: Gray

Certification: ISO9001:2008

| Selling Units | : | Pack/Packs |

|---|---|---|

| Package Type | : | Wooden Case And Anti-rust Bag |

| Picture Example | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

Small size but large volume generator and Motor Lamination is very suitable to be produced in the progressive punching way, which can produce high quantities in a short period of time, even the complete stator & rotor cores. The progressive punching method mainly relies on high-performance and high-speed punches and high-quality molds.

Though dies take a long time to build and cost higher, progressive punching is still the optimal solution for large volume motors. The products produced in this way have a very good consistency.

When the synchronous motor is running normally, the rotor speed and the synchronous speed of the stator magnetic field are in a synchronous state. However, when the load changes suddenly, due to the inertia of the rotor, the rotor displacement cannot be immediately stabilized around the new stable value.

Cut the silicon steel roll into the required width, and then directly send it to the high-speed press, which can stamp more than one hundred times per minute. Different from other stamping methods, the inside of the tool is complicated, and there are many cutters inside the tool, which respectively complete different steps. There is even a special stacking area inside the tool. The tool can cut out several rivets on each lamination. These rivets are compressed in the stacking area and each lamination is locked to each other.

Electrical lamination of mass-produced motors is very suitable to be produced in the progressive punching way, which can produce high quantities of Motor Laminations or motor cores in a short period of time. Though dies take a long time to build and cost higher, the products produced in this way have a very good consistency.

Packaging: Wooden Case And Anti-rust Bag

Productivity: 999999

Transportation: Ocean

Place of Origin: Henan, China

Supply Ability: 9999999

Certificate: ISO9001:2008

HS Code: 85030090

Port: QINGDAO,SHANGHAI

Payment Type: L/C

Incoterm: FOB,CFR,CIF,EXW,FAS,CPT

Hot Products

SEND INQUIRY